A San Antonio Product Liability Lawyer is a specialized civil litigator who represents injury victims in Bexar County and South Texas against negligent global manufacturers. Unlike general attorneys, we possess the technical resources to prove strict liability for defective automobiles, medical devices, and industrial machinery.

San Antonio Product Liability Litigation: Trial Lawyer Takeaways

- As your San Antonio Product Liability Lawyer, we hold global manufacturers accountable when safety systems fail on corridors like Loop 410 in Bexar County.

- Trevino Injury Law secured a $7.9 Million verdict for a crushed foot after rejecting a $1.3 million offer from the defense.

- We apply the crashworthiness doctrine when safety systems fail, holding manufacturers liable for enhanced injuries that go beyond the initial impact damages.

- Our legal team deploys forensic experts to preserve the black box and airbag module before spoliation destroys critical evidence in South Texas.

Do You Qualify For Full Compensation?

“The insurance company offered less than $20,000. I ended up with over a million.” – Jackie Galindo

The danger on our shelves is real. The 2023 CPSC Annual Report indicates that defective home structures alone cause nearly 3.9 million emergency room visits annually. Locally, this risk was highlighted by the 2025 CPSC recall of 850,000 Ozark Trail water bottles due to vision loss incidents. While these catastrophic failures alter lives, few victims recover fair financial compensation because their counsel fears the courtroom.

Trevino Injury Law levels the playing field. With over 80 personal injury cases taken to trial, we have the authority to battle corporate defense teams. We focus on holding manufacturers accountable for introducing dangerous items into the stream of commerce. We immediately preserve physical evidence and navigate complex statutes of repose to secure your future. Do not accept a lowball settlement for a product defect. Contact us at 210-TREVINO for a free consultation. Se Habla Español.

Do I Have a Valid Texas Product Liability Claim?

Yes, you have a valid case if you can prove the product was “unreasonably dangerous” when it left the manufacturer’s control and that this specific defect was the direct cause of your injury.

Under the Strict Liability standard codified in Texas Civil Practice & Remedies Code Chapter 82, you do not need to prove the manufacturer was ‘negligent’ or acted with malice. We focus on the product’s condition rather than the manufacturer’s conduct, establishing liability based on the defect’s existence at the time it left their control or knew about the flaw, only that the flaw existed and caused harm. This protective doctrine was firmly established in Texas by the landmark decision McKisson v. Sales Affiliates, Inc., 416 S.W.2d 787 (Tex. 1967), which shifted the legal focus entirely from the manufacturer’s conduct to the product’s dangerous condition.

Local juries in Bexar County District Courts evaluate “unreasonable danger” by weighing the utility of the product against the risk it poses to the consumer. For example, a knife is dangerous, but it is not “unreasonably dangerous” because its utility requires sharpness; however, a circular saw with a failing guard presents a risk that outweighs its utility. A critical distinction often arises regarding the burden of proof: while negligence focuses on the manufacturer’s conduct, strict liability focuses entirely on the product’s condition.

What Qualifies as a Defective or Dangerous Product in Texas?

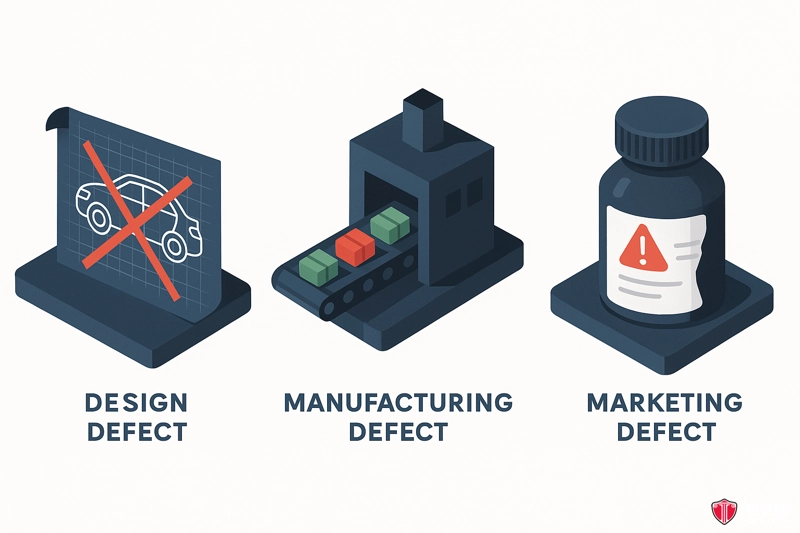

To succeed in a claim, the specific failure must typically fall into one of the following three distinct categories: design defects, manufacturing defects, or marketing defects. Identifying the correct type of defect is essential because the evidence required to prove a design flaw differs significantly from the evidence needed to prove a manufacturing error.

- Design Defect (Texas CPRC § 82.005): The design of the product itself was unsafe. To succeed under Section 82.005, we must prove that a flaw in the actual design existed and a ‘safer alternative design’ was feasible. That was both technologically and economically feasible, and the product’s risk outweighed its utility, rendering the vehicle unreasonably unsafe for normal use (e.g., an SUV with a center of gravity so high it is prone to rollover).

- Manufacturing Defect: An error in the assembly process made one specific unit dangerous while others remained safe. For instance, in January 2025, the CPSC announced a recall for approximately 16,000 bottles of Woolite laundry detergent sold on Amazon, citing bacterial contamination. This defect affected only specific lots sold to customers, including those in San Antonio, proving that even trusted household brands can fail quality control standards.

- Marketing Defect: The manufacturer failed to warn users of non-obvious dangers present even when using the product as intended, or committed a breach of warranty by failing to meet the safety standards promised (e.g., a pharmaceutical drug lacking warnings about severe side effects).

How Does a Liability Lawyer in San Antonio Find Who Is Responsible in the Full Chain of Distribution?

In a Texas product liability claim, responsibility often extends far beyond the company whose name is stamped on the box. To maximize your compensation, our legal team must identify every entity in the “stream of commerce” that contributed to the defect.

This process, known as ‘vertical privity,’ allows us to hold multiple parties accountable under the doctrine of Joint and Several Liability (Texas Civil Practice & Remedies Code § 33.013). Under this statute, a defendant found to be greater than 50% responsible can be held liable for the full amount of damages, ensuring that even if one defendant declares bankruptcy, other avenues for recovery remain open.

- Component Manufacturers: Often, the final product is assembled from parts made by third-party vendors. If a specific bolt in a steering column fails due to poor metallurgy, the maker of that bolt is liable alongside the car manufacturer. If you decide to file a lawsuit, we use subpoena power to trace part numbers back to their original foundries or factories, often located overseas, to establish jurisdiction.

- Assemblers and Installers: A product may be safe when manufactured but made dangerous during assembly. This is common in San Antonio trucking cases where local mechanics install aftermarket hydraulic lifts or beds onto chassis. If the installation was performed incorrectly, drilling into a frame rail where it wasn’t permitted, the installer bears liability for the structural failure.

- Wholesalers and Distributors: These “middlemen” facilitate the movement of goods. While they may not touch the product out of the box, they are strictly liable for passing a defective product down the line.

- Retailers and the “Innocent Seller” Exception: Under Texas Civil Practice & Remedies Code § 82.003, non-manufacturing sellers (retailers) are generally protected from liability unless specific exceptions apply. We can pierce this protection if the retailer knew of the dangerous or defective product, altered the product (e.g., a dealership lifting a truck), or if the manufacturer is insolvent or not subject to Texas jurisdiction.

Identifying these hidden parties requires a specific procedural tool known as Discovery. We utilize Subpoenas Duces Tecum to demand shipping manifests, quality control logs, and contracts between the brand name and the original equipment manufacturer (OEM). In many San Antonio trucking cases, this reveals that the liability lies not with the driver, but with a logistics company in another state that loaded the cargo improperly.

Does a Recall Confirm a Product Liability Action?

No, a recall notice alone is not sufficient proof of liability; you must still demonstrate that the injuries caused were the direct result of the specific recalled defect. While a recall issued by the NHTSA or the Food and Drug Administration (FDA) serves as powerful evidence that a defect exists, defense attorneys will aggressively argue “user error,” “intervening causes,” or lack of maintenance to break the causal link.

For instance, if you are injured in a car accident involving a vehicle subject to a recall for brake failure, but the accident was caused by another driver running a red light in Alamo Heights, the recall may be irrelevant to your specific crash. However, if the brakes failed on Loop 410 and caused a rear-end collision, the recall becomes a central piece of evidence. Manufacturers often issue recalls to limit future liability, but this action does not automatically concede fault for past injuries. We use the recall data as a starting point for our investigation, not the conclusion. Once the defect type is identified and linked to your injury, we must determine if the product failure occurred in a specific context, such as on the road.

When Are Manufacturers Liable for Defective Product Injuries in Crashes?

Vehicle manufacturers are liable when a safety system fails to perform as the product was intended during an accident, converting a standard crash into a “crashworthiness” product liability claim. This legal concept, known as ‘crashworthiness,’ was established in Texas by Turner v. General Motors Corp. (Tex. 1979). In this ruling, the Texas Supreme Court held that while manufacturers cannot prevent all accidents, they have a strict duty to design vehicles that reasonably protect occupants during a collision.

If a safety system fails on I-10, the manufacturer is liable for the resulting ‘enhanced injuries,’ particularly on high-speed corridors like I-10, Loop 410, and I-35, where traffic density and speed make safety systems critical. In these scenarios, if a seatbelt unspools or a roof crushes inward during a rollover, the manufacturer may be responsible for the “enhanced injuries”—harm that goes beyond what the initial impact caused, even if you used the product correctly.

We frequently navigate the complexities involving the Federal Motor Carrier Safety Administration (FMCSA) regulations when commercial vehicles are involved. It is crucial to differentiate between suing the at-fault driver for negligence (causing the crash) and suing the car maker for product liability (failing to protect you).

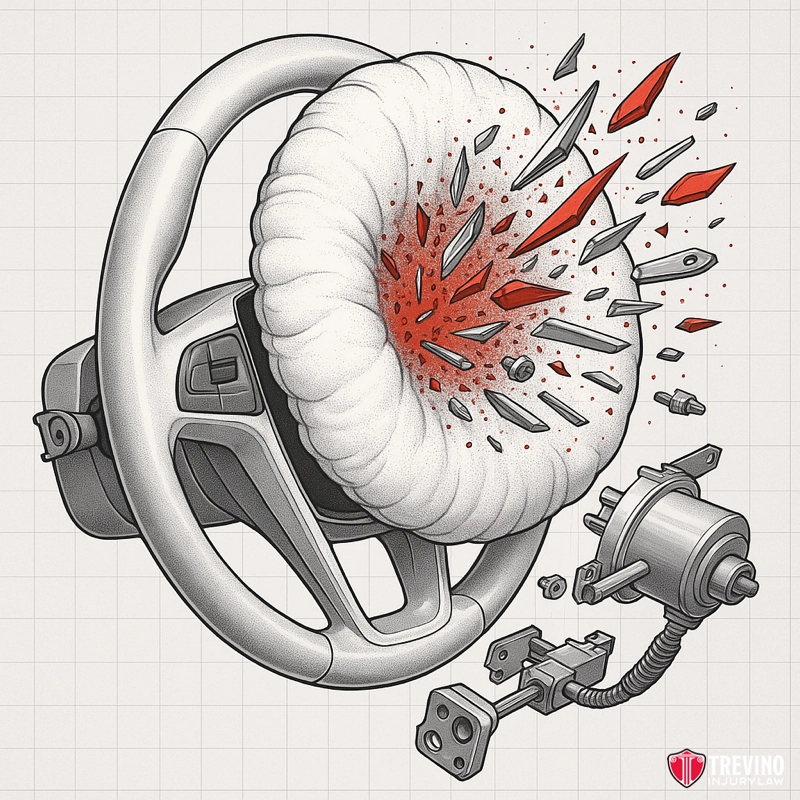

Can I File an Injury Claim If My Airbag Failed or Exploded?

Yes, you can sue if an airbag failed to deploy during a collision where it should have, or if it deployed with excessive force, sending shrapnel into the cabin. One of the most notorious examples is the Takata airbag inflator. Despite being an older recall, data from a 2025 CARFAX analysis reveals that an estimated 5.7 million vehicles are still on U.S. roads with these defective airbags today. NHTSA reports through September 2024 confirm these failures have been linked to at least 28 confirmed deaths in the U.S. alone.

If you are driving an older Honda or Ford in Helotes and your airbag deploys with excessive force, the manufacturer, not the other driver, may be liable. These failures often result in catastrophic injuries, such as blindness, traumatic brain injuries, or severe facial fractures. In these cases, it is vital that you seek medical attention immediately, which is distinct from the whiplash or bruising typical of the crash itself.

Preserving the vehicle is paramount in these cases. If the car is totaled and sent to a scrapyard in Von Ormy or Somerset, the “black box” (Event Data Recorder) and the defective airbag module may be lost forever. We act immediately to secure this evidence, which can prove the deployment criteria were met but the system failed. These cases require expert analysis to show that the sensor algorithms were flawed or that the propellant used in the inflator had degraded over time.

Who Is Liable for Tire Blowouts in Product Liability Cases in Texas?

Responsibility for a tire blowout often lies with the manufacturer for tread separation defects, though retailers can also be liable if they sold aged or damaged tires. Tire failures are particularly frequent on Loop 1604 and State Highway 151 due to the physics of “heat cycling.”

The extreme surface temperatures of San Antonio highways cause the rubber in older tires to expand and contract rapidly. This thermal stress accelerates the breakdown of the chemical bond between the steel belt and the tread, causing catastrophic delamination at highway speeds.

Retailers sometimes sell “aged tires”—tires that have sat on a shelf for years, drying out and becoming brittle, as if they were new. If a tire shop in Leon Valley sells you a six-year-old tire that subsequently blows out, both the shop and the manufacturer could be defendants. We analyze the tire’s DOT code to determine its true age and manufacturing plant. Proving a manufacturing defect typically involves demonstrating that the steel belts separated from the rubber due to poor adhesion practices at the factory, rather than road hazards like potholes or nails. While automotive defects are common, similar principles of strict liability apply when dangerous equipment fails in the workplace.

How Does an Experienced Product Liability Firm Prove the Defect?

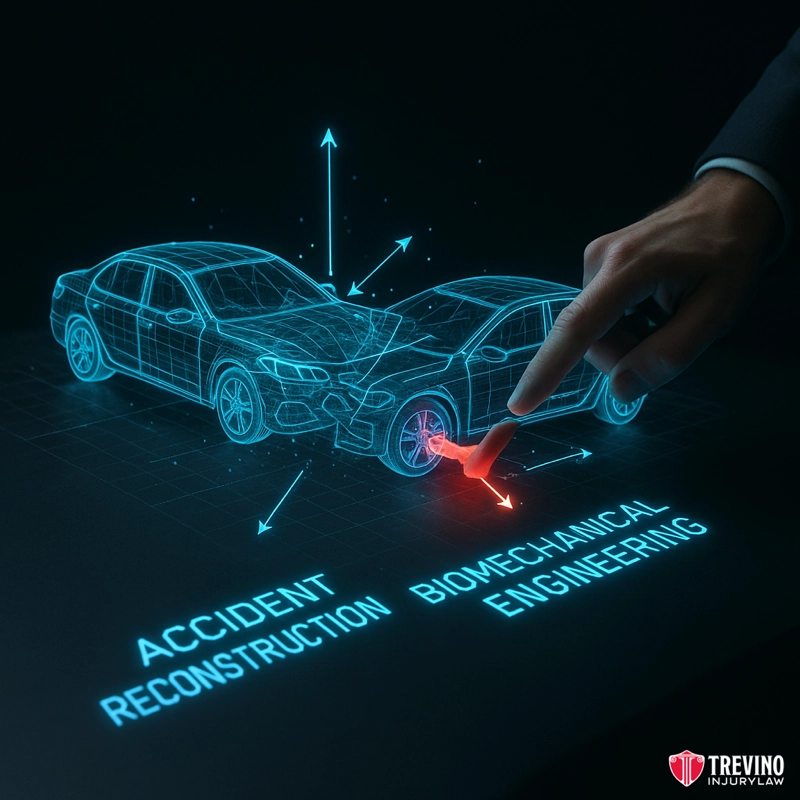

Winning a product liability case in Bexar County requires more than witness testimony; it requires irrefutable scientific proof that the product failed due to a flaw and not user error. “Settlement mill” firms and general injury lawyers often shy away from these cases because of the substantial upfront investment required to hire qualified forensic experts. At Trevino Injury Law, we front these costs to deploy a team of specialists who can scientifically reconstruct the failure.

Different defects require specific scientific disciplines to prove liability:

- Metallurgists and Materials Scientists: When a crane hook snaps or a tire blows out, we hire metallurgists to examine the fracture surface under scanning electron microscopes. They can determine if the metal failed due to “fatigue” (a long-term design flaw), “brittle fracture” (bad heat treating during manufacturing), or “overload” (user error). Proving that a microscopic impurity in the steel caused the catastrophic failure is often the turning point in industrial accident cases.

- Biomechanical Engineers: Defense attorneys will argue that your injuries were pre-existing or caused by something other than the defect. Biomechanical experts apply the laws of physics to human anatomy, calculating the forces exerted on your body during the crash. They can prove, for instance, that your spinal fracture could only have occurred because the seatbelt failed to lock, allowing your body to strike the dashboard.

- Human Factors Experts: In “Failure to Warn” cases, we use human factors psychologists to analyze how people interact with machines. They testify on whether a warning label was conspicuous enough, or if a control panel was designed in a confusing way that made “operator error” inevitable and foreseeable.

This level of technical depth allows us to dismantle the defense’s argument that you were simply “clumsy” or “negligent.” We do not just claim the product was bad; we prove why it failed at a molecular or structural level.

Can You Sue If You Were Harmed by a Defective Product at Work?

Yes, industrial workers can file a third-party product liability lawsuit against the equipment manufacturer if a design flaw or unguarded machine caused the injury, separate from their workers’ compensation claim.

This is a critical legal avenue for workers in the Eagle Ford Shale and San Antonio’s manufacturing sectors who are otherwise limited by the ‘Exclusive Remedy’ provision (Texas Labor Code § 408.001).

The danger facing Texas workers is statistically proven. According to the U.S. Bureau of Labor Statistics (BLS) Census of Fatal Occupational Injuries for 2023, Texas recorded 564 fatal occupational injuries in a single year. Of those deaths, the BLS confirms that 86 were specifically caused by “contact with objects and equipment”, such as being struck by or caught in machinery. Furthermore, the 2023 BLS data shows that 229 of these fatalities occurred in production, transportation, and material moving roles, verifying that the risk is highest for those who interact daily with conveyors, forklifts, and hydraulic presses.

While this statute (Exclusive Remedy) prevents employees from suing their subscribers-employers for standard negligence, it does not protect the manufacturers of the defective equipment that caused the injury. By filing a third-party claim against the manufacturer of a defective forklift, conveyor belt, or hydraulic press, you can recover damages that workers’ compensation does not cover, such as full lost wages and pain and suffering. These accidents often occur in industrial hubs like Kirby or near the Port San Antonio area.

A common defect involves the removal or lack of safety guards that prevent crushing injuries. Manufacturers have a duty to design machines that are safe for their intended use and foreseeable misuse, meaning they cannot simply blame the worker if a safety feature could have prevented the accident.

How Has Our Law Firm Maximized Results for Injury Victims?

Our aggressive trial preparation has forced manufacturers and insurance companies to pay significantly more than their initial settlement offers because they know we are willing to let a jury decide the outcome. When corporate defendants see that a firm is trial-ready, their risk calculation changes, often leading to substantial increases in compensation.

- $7.9 Million Verdict: We won this verdict for a client with a crushed foot against Farmers Best International LLC after rejecting a $1.3M offer. The jury recognized the severity of the injury and the manufacturer’s failure.

- $536,007 Verdict: In Arriaga v. Montemayor, we secured 107 times the pre-trial offer of $5,000, demonstrating our ability to prove the true extent of damages even when the defense minimizes them.

- $17 Million Settlement: We achieved this result in a wrongful death 18-wheeler case involving complex liability, securing the future for our clients and their families after a tragic loss.

These claims often result in the highest verdicts due to the severity of the injuries, but the same aggressive representation is required when fighting global pharmaceutical giants.

How Do We Handle Common Product Liability Claims for Medical Devices?

Medical device lawsuits typically proceed as “mass torts” or Multi-District Litigation (MDL), where thousands of individual claims against a manufacturer are consolidated for pre-trial proceedings while retaining their individual value. This structure allows victims in Stone Oak or South Texas to pool resources against massive defense teams without losing the specific details of their own injury.

Patients receiving faulty hip implants, hernia mesh, or transvaginal mesh often face a “David vs. Goliath” battle. Unlike medical malpractice claims that focus on a doctor’s error, these lawsuits target the device’s inherent failure. Global pharmaceutical companies have virtually unlimited resources to defend their products.

In an MDL, a federal judge manages the discovery process, identifying the “smoking gun” documents that show the company knew of the defect, benefiting all plaintiffs. However, unlike a class action, your settlement is based on your specific medical complications, surgeries, and suffering, not a generic formula.

Should Injury Victims in San Antonio Join a Class Action or Sue Individually?

For catastrophic injuries, filing an individual lawsuit is almost always superior to joining a class action, as class settlements often dilute the compensation needed for long-term medical care. Class actions are designed primarily for economic losses where many people suffered small damages, such as a refund for a defective toaster.

In personal injury cases, a “class” approach fails to account for the unique pain and life changes of each victim. A person who required revision surgery and lost their ability to walk deserves far more compensation than someone who received the same device but suffered only minor irritation. By filing individually (often within an MDL), you maintain control over your case and settlement demands. Defense attorneys prefer class actions for injuries because they can settle thousands of claims cheaply; we fight to keep your claim separate to ensure your specific damages are fully recognized.

Why Do I Need a San Antonio Product Liability Attorney Willing to Go to Trial Against Manufacturers?

Global manufacturers and their insurance carriers calculate every settlement offer based purely on risk assessment; if your attorney is not known for taking cases to verdict, the financial “risk” of a large jury award is non-existent, and the settlement offer will be minimal. These corporations maintain databases of plaintiff attorneys, knowing exactly who will settle cheap and who will fight to the end.

Many firms in San Antonio operate as “settlement mills,” processing hundreds of claims without ever stepping foot inside the Bexar County Courthouse. They cannot threaten a manufacturer with a trial because they lack the experience or resources to conduct one. Trevino Injury Law operates differently. With over 80 personal injury cases taken to trial, we position your claim as a legitimate threat to their bottom line. We view ourselves as the “David” to their “Goliath,” using the courtroom to equalize the power dynamic. When a defense team knows we are ready to present evidence to a jury—whether the accident happened in Helotes or downtown San Antonio—they are far more likely to offer a fair settlement to avoid the uncertainty of a verdict.

However, even the most aggressive trial strategy cannot save a claim if the strict legal deadlines for filing have already passed.

H3: What Is the Deadline to File a Product Liability Claim in Texas (Statute of Limitations)?

The standard Statute of Limitations (Texas Civil Practice & Remedies Code § 16.003) for personal injury in Texas is strictly two years. You must file suit not later than two years from the date the cause of action accrues. If you miss this window, you may lose your right to recovery.

This “Discovery Rule” is critical in product liability cases involving pharmaceuticals or toxic exposure, where the harm, such as cancer from a defective drug, may not manifest until years after the product was used. However, distinguishing between the filing deadline and the product’s age limit is essential for your case’s viability.

Comparison of Critical Deadlines:

| Legal Deadline | Time Limit | Critical Exception |

| Statute of Limitations | 2 Years | Starts from date of injury or discovery of injury. |

| Statute of Repose | 15 Years | Starts from date the product was sold, regardless of injury date. |

| Notice of Claim | 90 Days – 6 Months | Applies only if suing a government entity (city/state). |

How Do We Calculate Future Costs for Injury Victims in San Antonio? The Life Care Plan

Product liability cases frequently involve life-altering injuries—amputations from industrial machinery, paralysis from SUV rollovers, or traumatic brain injuries from exploding devices. In these scenarios, a simple stack of past medical expenses does not reflect the true cost of the injury. To ensure you are compensated for the lifetime impact of the defect, we commission a Life Care Plan.

A Life Care Plan is a comprehensive economic and medical assessment that projects your needs for the rest of your life. We collaborate with vocational rehabilitation specialists and economists to calculate:

- Future Medical Inflation: Medical costs rise faster than the general inflation rate. We account for the cost of surgeries you will need 10, 20, or 30 years from now.

- Durable Medical Equipment: This includes not just the cost of a wheelchair today, but the cost of replacing that wheelchair every five years, modifying your home in Stone Oak or Helotes for accessibility, and purchasing adapted vehicles.

- Loss of Earning Capacity: If a defective machine leaves you unable to return to your high-paying job in the Eagle Ford Shale, we calculate the difference between what you would have earned over your career versus what you can earn now.

- Household Services: If your injury prevents you from performing daily tasks, mowing the lawn, cleaning, or cooking, the cost of hiring professionals to do this work is compensable damages.

Insurance adjusters for manufacturers will always base their offers on your past bills. We fight for your future security, using these detailed economic models to demand a settlement that provides for you and your family for decades to come.

Does the Statute of Limitations Pause for Minors?

Yes, if a child is injured by a defective product, the two-year deadline is “tolled” (paused) until they turn 18, giving them until their 20th birthday to file suit to recover damages for their own pain and suffering.

Can I Sue If I Lost the Receipt for the Defective Product?

Yes, you can still sue without a receipt if other evidence, such as credit card statements, witness testimony, or the product’s unique serial number, proves you purchased or used the item.

Do I Have to Pay Upfront for a Product Liability Lawsuit?

No, Trevino Injury Law operates on a contingency fee basis, meaning we advance all litigation costs and you only pay legal fees if we win your case. This includes the substantial expense of hiring expert witnesses—engineers, accident reconstructionists, and medical professionals—who are necessary to prove the defect exists; we cover these costs upfront so your financial situation never prevents you from seeking justice.

How Does the Texas Statute of Repose Affect Older Products?

The Texas Statute of Repose creates an absolute deadline, barring any product liability claim filed more than 15 years after the product was originally sold by the manufacturer, regardless of when the injury occurred. This law, found in Texas Civil Practice & Remedies Code Chapter 82.008, serves as a “hard stop” designed to protect manufacturers from indefinite liability.

This statute frequently affects workers injured by older industrial machinery in South San Antonio manufacturing plants or drivers of older vehicles. If a punch press was sold in 2005 and injures a worker in 2024, the claim against the manufacturer is likely barred, even if the injury just happened. However, exceptions may apply, particularly if the manufacturer expressly warranted the product for a longer life or if the injury involves a latent disease. We meticulously trace the “date of first sale” to determine if your claim falls within this strict window. Even with a valid timeline, you can lose your ability to recover compensation if the physical proof of the defect is missing.

What Happens If You Discard or Repair the Defective Product?

If the defective product is thrown away, repaired, or altered before our experts can examine it, your case may be dismissed under the doctrine of “spoliation of evidence.” In product liability law, the product itself is the “star witness,” and the manufacturer has a legal right to inspect it to prepare their defense.

This is why you must never let an insurance company take your totaled car to a salvage yard or allow your employer to “fix” a broken machine immediately after an accident. If the evidence is gone, we cannot prove the defect existed at the time of the crash. Whether it is a burnt-out toaster in Olmos Park or a failed tire on I-35, secure the item immediately and do not attempt to repair it.

While preserving evidence prevents your case from being dismissed, the defense will still try to reduce your payout by blaming you for the accident.

Can You Still Recover Damages If You Were Partially at Fault?

Yes, under Texas Civil Practice & Remedies Code Chapter 33 (Proportionate Responsibility), you can still recover damages as long as you were not more than 50% responsible. Specifically, Section 33.001 bars recovery only if your percentage of responsibility is greater than 50%; otherwise, your damages are simply reduced by your percentage of fault. The court will reduce your final compensation award by the percentage of fault assigned to you.

For example, if a jury awards you $1 million for a rollover accident but finds you were 20% at fault for speeding, you would receive $800,000. Defense attorneys will aggressively argue “product misuse”, claiming you used the tool incorrectly or modified the vehicle, to push your fault percentage above 50%, which would bar you from receiving anything. As your San Antonio Product Liability Lawyer, we fight to keep the focus on the manufacturer’s design failure rather than your split-second reaction during the crisis.

Defeat the Manufacturer: Call Trevino Injury Law Now

Global manufacturers protect their profits, not your safety. They rely on delay tactics and hope you hire a “settlement mill” that fears a fight. We are different. We are The Trial Authority. We strip away their defenses and force them to pay.

We possess the resources to battle billion-dollar corporations. Our aggressive strategy secured a $17 million settlement in a complex wrongful death case, ensuring the family’s future was secure. We dominate the Bexar County Courthouse and refuse to back down.

Call 210-TREVINO for a free, confidential consultation. Se Habla Español. You pay nothing unless we win—No Win, No Fee.